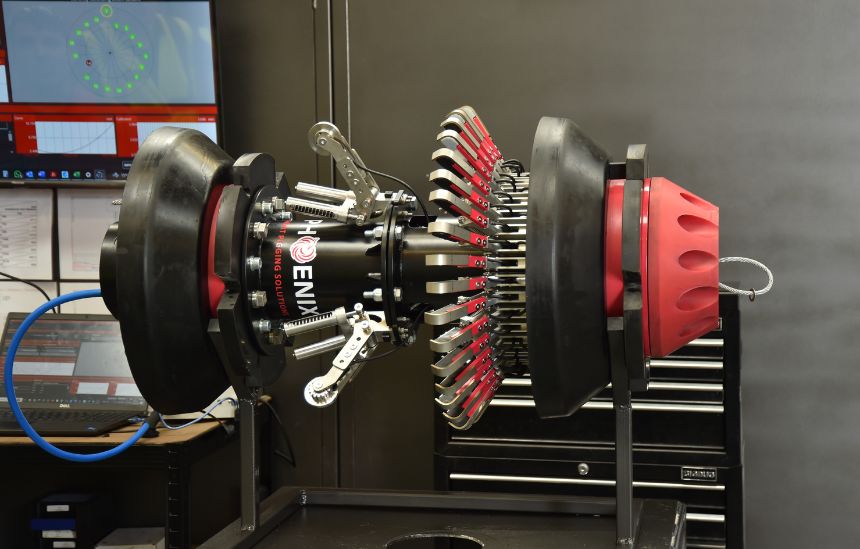

iNPIPE PRODUCTS™ Phoenix Debris Mapping Tool uses the latest hi-tech sensors to produce a highly accurate and detailed snapshot of a pipeline’s internal condition in real time.

Unlike competing systems that often take weeks to deliver post-pigging results, the Phoenix Debris Mapping Tool generates comprehensive reports within minutes from the data collected and accuracy down to 0.1mm.

The award-winning company believes this revolutionary technology has the potential to save clients hundreds of thousands of pounds.

“The Phoenix Debris Mapping Tool is a groundbreaking advancement, utilising the most advanced sensors in the industry,” said Barry Ritchie, General Manager of iNPIPE PRODUCTS™ Aberdeen Service Centre.

“It captures up to 144,000 data points every second where required, delivering an unparalleled volume and precision of data across a pipeline network. This tool provides pipeline operators with a full 360-degree internal assessment, identifying everything from debris and damage to temperature fluctuations and internal joint measurements.”

“The Phoenix Debris Mapping Tool truly gives both small and large, commercial pipes the ultimate MOT, ensuring you have the perfect pipeline picture that will provide businesses with peace-of-mind in knowing that money won’t be wasted during in-line pipeline inspections.”

Founded 40 years ago, iNPIPE PRODUCTS™ has established itself as a pioneering leader in pipeline pigging, maintenance, isolation, and testing products worldwide. The North Yorkshire-based company, with a service centre footprint based in Aberdeen has developed a comprehensive suite of solutions for industries dependent on pipeline networks, from energy and petrochemicals to food and water. The Phoenix Debris Mapping Tool is expected to be particularly beneficial in sectors like water, where aging infrastructure presents unique challenges.

Simon Bell, Managing Director of iNPIPE PRODUCTS™, said, “The water industry has faced well-documented issues with leaks due to aging pipes made of materials like carbon steel, cast iron and even clay. Our technology enables us to map entire pipelines, providing vital data that can help locate and address problems before they become costly failures”.

As iNPIPE PRODUCTS™ continues to innovate, it remains dedicated to expanding its portfolio of cutting-edge solutions, ensuring clients benefit from a one-stop solution that enhances the performance and reliability of their pipeline assets.