Sulzer will unveil the latest addition to its market-leading structured packing product family – MellapakEvo™ – at ACHEMA 2024 in Frankfurt, Germany from 10-14 June. ACHEMA attendees will have the opportunity to see first-hand how the new innovative design can significantly boost the efficiency of distillation columns by up to 40%, for unparalleled performance in mass transfer technology.

Engineered to ensure reduced pressure drop, MellapakEvo™ offers maximum performance and minimum energy consumption for both cost savings and environmental benefits. The MellapakEvo structured packing has been developed to enhance the efficiency and capacity of distillation columns, maximizing performance while minimizing energy consumption with a lower pressure drop. An innovative new design allows it to offer up to 40% greater efficiency or 20% higher capacity when compared to the standard equivalent structured packing type.

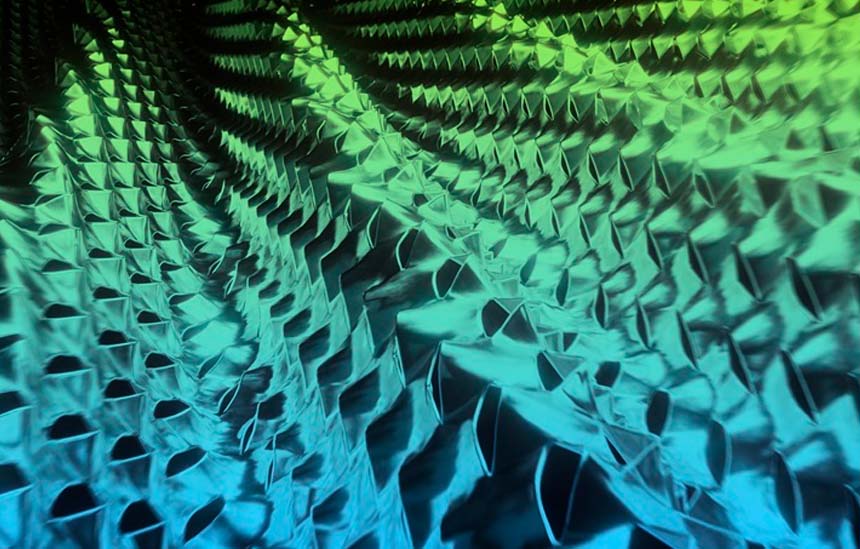

The increased performance of the MellapakEvo structured packing is a result of several innovative changes to its structure. The optimized packing geometry of MellapakEvo enhances liquid spreading and improves liquid surface renewal – which is critical to the mass transfer required in a distillation column. Greater interaction between liquid and gas phases ensures a more efficient mass transfer. Moreover, the structured packing is suitable for a wide range of distillation processes. It is ideal for use in diverse applications in the chemical processing industry where its ability to offer both high efficiency and a low-pressure drop is vital.

MellapakEvo will be revealed to the public for the first time at ACHEMA 2024, the leading global trade show for the process industries. There, attendees will be able to gain first-hand information about the new product and learn more about its potential applications from Sulzer experts.

Sulzer’s Chemtech Division President Uwe Boltersdorf said: “On behalf of the Chemtech team, I am incredibly proud to launch our new MellapakEvo structured packing product to the market. We strive to meet or exceed our customers’ requirements by developing superior products through continuous innovation and enhancement of our market-leading designs. As a highly energy-intensive process, companies operating in the field of distillation are always in need of solutions that offer higher efficiency and greater capacity. We look forward to the response of the ACHEMA attendees who will experience the unparalleled performance of MellapakEvo first.”

Sulzer is ACHEMA 2024’s official innovation partner. In addition to MellapakEvo, the company will be showcasing a range of interactive mass transfer components, and a holographic display will provide a new perspective on its latest innovation. Alongside this, the stand will host virtual environments that guide attendees through an array of Sulzer solutions for chemical processing plants, including falling-film crystallization, distillation, purification and both expandable polystyrene (EPS) and polylactic acid (PLA) production.

Sulzer experts will also be making three presentations at the trade show, covering topics ranging from carbon capture to the evolution of the Mellapak family of structured packings. Chemtech Division President Uwe Boltersdorf will participate in the show’s closing panel discussion on how the process industry can mimic natural ecosystems for effective carbon capture and storage.